Case Studies

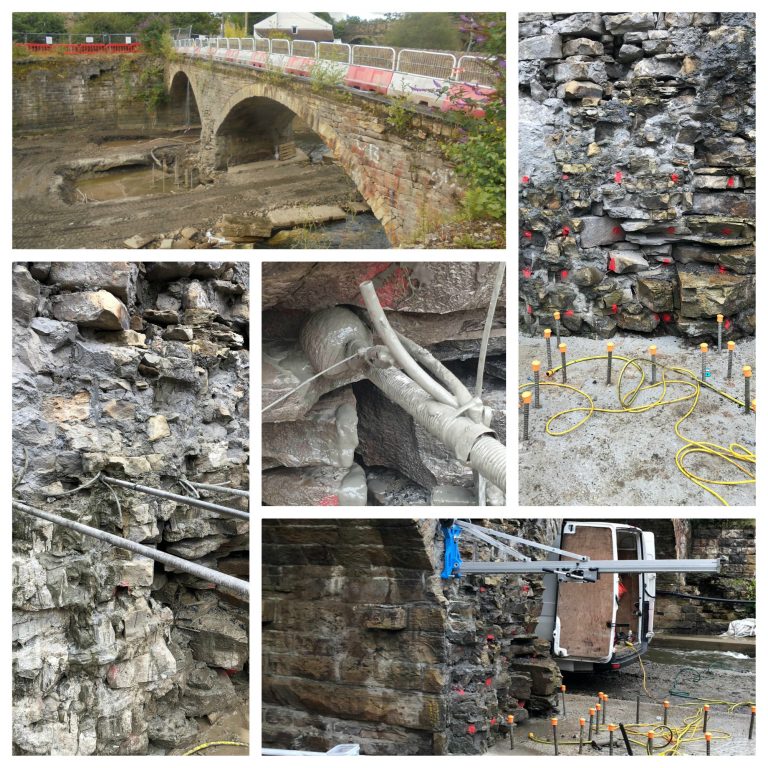

Project: Kay Street Bridge

Client: AE Yates Ltd

Works have begun on Kay Street Bridge, a road bridge in Ramsbottom which is being widened to create a pedestrian footpath. Substantial stabilisation works are required to allow this extension of the bridge to be successful.

Part of these stabilisation works involved the installation of Helifix SockFix Anchors.

SUKR were appointed to undertake these works. Core drilling was carried out using specialist mining cores specifically manufactured for this job to allow horizontal drilling to a depth of 3m.

The SockFix Anchors were then installed to a depth of 3m, leaving 1.5m protruding for the Client to then cast around, ensuring the new extended area of the bridge will be strengthened by these.

Posted in: Structural Repair & Helifix Micro Piling

Project: Cumber Lane Bridge, Whiston

Client: AMCO Rail

Situated on the busy Liverpool-Manchester railway link, Cumber Lane bridge was highlighted for an overhaul due to Health and Safety reasons. Both parapet walls did not meet the new legislation relating to pedestrian trafficked bridges whereby the walls had be set at a height of 196cm. This meant that the top 2 layers of existing stonework had to be carefully removed and set aside on the West elevation and replaced with new stone and associated stone copers.

Each stone had to be manufactured and installed in its exact place in line with Network Rail’s site specific drawings using high grade stainless steel dowels and performance grout.

Works were executed within a tight programme which included a series of Saturday and week night shifts. This was to reduce disruption to the surrounding residents, schools and most importantly the nearby Whiston Hospital which Cumber Lane Bridge provides an important road link for.

Working closely with AMCO Rail, SUKR managed the rail side access element of the works by way of specifying and hiring the countries only wagon-mounted MEWP which allows up to 3 operatives to work within it’s basket any one time to allow programme deadlines to be met. The rail side element of the works required vast amounts of experience from both AMCO and SUKR to plan out the programme due to the narrow width of the bridge itself and the added risk element of working closely with the railway’s overhead electrified cables. Due to the short time frame in which the cables can be shut off, this meant that the track side works could only be completed on a Saturday evening within a shorter possession.

Posted in: Stone Restoration & Conservation

Project: Stone Repair and Facade Cleaning - Deansgate

Client: Contract Services

Situated on the edge of Spinningfields in Manchester, this Grade II listed building’s facade was in desperate need of attention both internally and externally to allow this historic building to provide up to 45,000 sq ft of Grade A office space, along with over 17,000 sq ft of retail space on Manchester’s highest profile street. SUKR were appointed by Contract Services to carry out the restoration programme of the external facade which included Doff cleaning, pointing and stone repairs to the delaminated sandstone ashlar on window reveals, cills and entablature.

The main element of works for SUKR’s skilled craftsman focused around the careful removal of all defective stone work; followed by the installation of stainless steel dowels and wire, set into pre-drilled resin filled holes to allow the specified hand placed repair mortar to progressively restore and shape the repairs back to their original profile.

All of the contracted works were completed on programme, within budget and to the satisfaction of the client and appointed Architect.

Posted in: Stone Restoration & Conservation

Project: East Riding Leisure, Bridlington

Client: East Riding Leisure

East Riding Leisure, Bridlington is a £25 million development replacing the original building whose fabric and infrastructure was deteriorating to such a level that the ongoing maintenance requirements dictated the site was no longer sustainable as a going concern.

During construction an issue was discovered with the recently installed Sports Hall slab, with several sections of the slab requiring additional strengthening to relieve hogging stresses in excess of reinforcing bar installed in the slab.

Two options were proposed:

1) Hydro-demolish areas of the slab to a depth of 80mm, installation of new steel with a minimum of 30mm cover, and concrete reinstatement to match the existing grade strength.

2) Carbon fibre strengthening in lieu of traditional reinforcement to the top surface of the recently constructed concrete slab.

Specialist UK Restorations employed the services of Curtins Consulting to produce a series of scheme designs to suit availability/cost effectiveness of Sika products, and a detailed design of one product for use in lieu of proposed traditional H8 reinforcing bar.

We were awarded the contract due to both the cost effective nature of the proposed solution, and also the non-intrusive nature which allowed other trades to continue working throughout. The specified product was SikaWrap-301C which is a unidirectional woven carbon fibre fabric. All works were successfully complete within a 2 week window to ensure there was no impact on the critical path.

Posted in: Concrete Repair, Cathodic Protection & Protective Coatings

Project: Malthouse Lane Flats

Client: Rykneld Homes

Built in the early 1960’s, two storey Malthouse Flats are housing association properties that had developed structural problems. The masonry cracking was identified as being the result of subsidence due to inadequacies in the foundations.

The client commissioned a detailed ground investigation and, during excavation works, contractors discovered some cellars belonging to terraced houses that had previously occupied the site.

Cost-effective structural repairs were required that would rectify the faults and stabilise the properties, preventing any further subsistence and building damage.

Using the client’s ground investigations, Helifix devised a suitable repair scheme using its Dixie micro-piles to overcome the subsidence problems, and the Helibeam system to secure the damaged masonry. These were specified as they could be rapidly and efficiently installed using lightweight equipment externally, therefore causing minimal disruption to residents and a cost effective solution to leave the properties visually, unaltered.

As a Helifix approved installer, SUKR were appointed to carry out the works as per the above scheme.

Holes were dug adjacent to the foundations and notches cut into the building’s footings. Nine micro-piles were then driven to a depth of 10m in order to reach the load bearing bedrock and achieve the required torque.

Adjustable ‘L’ shaped brackets were fitted to the piles and placed under the foundations. They were then jacked up until the specified safe working load was achieved, with the piles then fully supporting the building loads.

Approximately 60m of stainless steel HeliBars were bonded into appropriate mortar beds with HeliBond cementicious grout to stitch the cracked brickwork and restore structural integrity.

Comments passed from Mrs Eaton, a resident of Malthouse Lane, Ashover, not a tenant of these flats but has lived in Ashover all of her life:

‘I have never seen such good workmen in all my life. They worked so hard. They dug and dug until all I could see were their heads! I didn’t hear any noise from them. They were here from 8am until 5pm everyday, sometimes later, but they didn’t disturb me at all. Their vans didn’t get in the way. We get a lot of tractors and farm vehicles on Malthouse Lane but they left plenty of room and made sure they didn’t cause an obstruction. They just got on with their work, I couldn’t fault them at all – and I am a very picky woman!’

Posted in: Structural Repair & Helifix Micro Piling Project: Concrete Column Repair - Barrow Mill

Client: Kimberly-Clark

SUKR were appointed by Jacobs Engineering to carry out remedial works to an existing load bearing reinforced concrete column at Kimberly-Clark’s Barrow Mill factory. The cracking was shown to pass through the column and was deemed a H&S risk in need of urgent repair.

The first stage of the repair was to restore the structural integrity to the area surrounding the damaged column. This was achieved in two stages, firstly we installed 2 steel brackets either side of the column at first floor level. The second stage was to open up two areas of brickwork either side of the column, allowing us to install RSJ’s and supporting Heavy Duty Acrow Props/Strongboys.

The extent of the concrete removal highlighted the poor condition of the column, and 11 days after completion of the reinstatement, a cube test result returned with a compressive strength of 64.5N/mm2.

Comments passed on from Jacobs Engineer on site: ‘Please thank Danny and Mark for their efforts and patience and the test cube results together with the consistency of the well compacted material shows the quality of their work.’

Posted in: Concrete Repair, Cathodic Protection & Protective Coatings

Posted in: Concrete Repair, Cathodic Protection & Protective Coatings

Project: Structural Repairs - Bollards Court, Chester

Client: Westby Homes

Westby Homes instructed SUKR to reinstate the structural integrity of the masonry at Bollards Court, a three storey masonry building showing historic cracking to the rear left hand corner. Under the requirements of the party wall agreement, Wesby Homes were to ensure that no further damage occurred during the development works of the adjacent site. The cracks were vertically stepped at various locations up the height of the rear left corner of the building, which were believed to be caused by historic settlement of the foundation. The cracking had been monitored over a period of time and results indicated the cracking was not progressive.

A combination of Helifix Helibars, HeliBond grout & CemTies were installed as per the design to tie the defective masonry together whilst creating deep masonry beams to distribute the structural loads. As an approved installer we were able to offer a 10 year Helibeam System Approved Installer Guarantee which also falls under the Consumer Protection Association Insurance Backed Guarantee Scheme.

Posted in: Structural Repair & Helifix Micro Piling

Project: Bran Sands ETW, Middlesborough

Client: Northumbrian Water

Specialist UK Restorations were appointed by BAM Nuttall to address a number of issues affecting the existing reinforced concrete Final Settlement Tanks (FST’s) at Bran Sands Effluent Treatment Works, for Northumbrian Water Limited.

Vertical cracks were present through the full section of the FST launder channel walls at regular intervals, and these cracks in conjunction with the abrasion of the scraper mechanism wheel, had resulted in spalling and wearing away of the top surface of the launder channel concrete walls. Specialist UK Restorations, in conjunction with Sika Ltd, produced a full material specification to alleviate the full list of defects as highlighted by the structural report prepared by AMEC.

In order to allow the concrete repair works to be undertaken we first used abrasive blast cleaning to remove the existing epoxy tar coating. All damaged concrete was then cut back and removed down to a sound base. As per the specification we carried out in the initial repairs by applying Sika MonoTop-610, which acts as a bonding bridge for the MonoTop concrete repair mortars. Sika MonoTop-615 high build repair and re-profiling mortar was then trowel applied, prior to applying Sika MonoTop-620 cementitious smoothing coat/leveling mortar and pore sealer. Each area being reinstated back to its original line and level incorporating any surface features that were previously present e.g. rebates, chamfers and the like. Due to the chemical structure of the effluent housed in the fully restored tanks, SUKR also applied Sika Poxitar F, a heavy duty protective coating for steel and concrete structures.

Upon completion of the remedial works, SUKR had as much as is reasonably possible, returned the tanks to their original design condition. Providing a smooth finish to allow the scraper wheel to travel along, but also be resistant to abrasion from the action of the scraper wheel.

Posted in: Concrete Repair, Cathodic Protection & Protective Coatings

Project: Brickwork Enhancement, Spandrel Works

Client: Network Rail

Little Salkeld Viaduct, also know as Dodds Mill Viaduct, is to be found in the Eden district of Cumbria, a few miles to the North-East of Penrith. The Viaduct consists of 7 arches, is 60 feet in height, and 134 yards long.

As part of Network Rails Asset Management strategy, the London North West route has experienced significant investment, in an effort to enhance, renew and maintain infrastructure. Works to little Salkeld Viaduct were carried out as part of this investment once Network Rail Asset Engineers had highlighted the need for brickwork enhancement works to each of the 7 spandrels forming the viaduct.

Specialist UK Restorations were appointed via AMCO Rail to carry out the works as per Network Rail Standard Design Drawings, and as outlined in the remit items of each detailed repair schedule. Due to the scaffold being erected to individual arches in stages and on pre-determined dates, it was paramount that we managed our workloads in line with the agreed programme.

As part of the brickwork enhancement remit, re-pointing was carried out to open joints throughout the spandrel walls, with areas of cracking and joint fractures undergoing stitch repairs and re-pointing as per Network Rail Standard Design Drawings NR/CIV/SD/101A, 106A & 107A.

The major element of the works consisted of several large areas of brickwork re-casing, as per NR/CIV/SD/101A & 103A. In certain locations spalling up to 190mm deep was evident, and in others the first course of arch rings had dropped noticeably.

Posted in: Structural Repair & Helifix Micro Piling

Project: Waterproofing and Concrete Repairs

Client: Stockport Homes

Specialist UK Restorations were appointed Principal Contractor on a balcony repair and refurbishment scheme on behalf of Stockport Homes ltd. Stockport Homes is a limited company that exists to manage the housing stock owned by Stockport Metropolitan Borough Council.

Stockport Homes undertook structural investigations at seven low-medium rise flats which highlighted numerous defects in respect of the concrete canopies and balconies. The balconies had a thin asphalt coating that continued into the drains and was also coved up the wall. The asphalt had begun to fail and this could clearly be seen around the perimeter coving and the drains, with the asphalt apparently leaking water due to localised evidence of steel corrosion to the balcony soffits.

SUKR were appointed to carry out, in no particular order, core holes through the balcony slabs prior to installing new and improved drainage, concrete repairs to the soffit, face and balcony floor, anti-carbonation coating to soffits (balconies cast in-situ), through coloured silicone render to soffits (pre cast panel balconies), balcony coating/waterproofing.

SUKR specified an advanced concrete repair system from Sika, including the MonoTop repair system, anti-carbonation coating SikaGard 675W, with the fast cure balcony coating Sikafloor-415 for the recoating to the balconies. Not only did this provide a cost effective, reliable and efficient solution, the quick curing abilities of the Sikafloor-415 system enabled the residents to remain in-situ throughout the full duration of the programme.

Posted in: Concrete Repair, Cathodic Protection & Protective Coatings

Posted in:

Posted in: